As we approach 2026, the packaging industry is experiencing one of the most significant periods of transformation in decades. Economic pressures, workforce shortages, sustainability demands and rapidly advancing automation technologies are reshaping how manufacturers produce, protect, and distribute goods. Companies across food & beverage, pet food, nutraceuticals, industrial goods, and consumer packaged goods (CPG) are rethinking their operations from the ground up – not simply to keep pace with competitors, but to remain viable in a global market defined by speed, accuracy, resilience, and flexibility.

At QuantumPak, we work closely with packaging operations of all sizes, giving us a direct view into the challenges manufacturers face and the emerging technologies that will define the industry’s next chapter. Based on thousands of hours of engineering, implementation, customer feedback, and market analysis, we’ve identified the top three trends that will shape packaging in 2026.

Trend #1: Automation Becomes Non-Negotiable

The move toward automation is not new. What is new is the speed at which companies are now adopting automated solutions—and how essential automation has become for meeting production demands that continue to escalate year over year.

Why automation is accelerating

Several forces are driving rapid automation adoption:

- Labor shortages continue to affect nearly every industry, specially manufacturing and food production.

- Demand for higher throughput—retailers and distributors expect faster replenishment, shorter lead times, and consistent supply.

- Error reduction requirements—for code dating, weight accuracy, sealing integrity, and traceability.

- Cost pressures—automation reduces waste, rework, and product giveaway.

- Workplace safety—machines now perform repetitive and high-intensity tasks previously done manually.

Automation is no longer a value-add. It’s the only way many companies can meet demand without expanding their workforce or sacrificing reliability.

What automation looks like in 2026

By 2026, automation is expected to be deeply integrated across packaging lines:

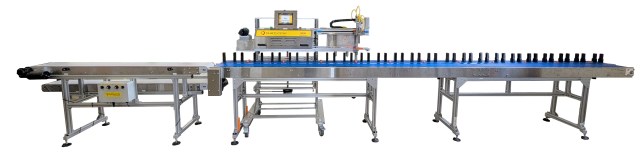

- Advanced bag sealers with synchronized conveyors, PLC control, and integrated vacuum/gas-flush systems

- Vibratory and multi-lane weigher systems capable of high precision and semi-autonomous calibration

- Automated code-dating using TIJ or CIJ printers and centralized data control

- Bag handling systems – like QuantumPak’s fingers system – designed to streamline small-bag production

- Vision systems for inspection, verification, and quality control

- End-of-line automation including case erectors, case packers, and palletizers

Companies adopting automation experience measurable improvements:

- 20–40% increase in throughput

- Reduced labor dependency

- Dramatically higher sealing consistency

- More accurate fills and weights

- Lower product waste

- Faster changeovers

- Better compliance with retailer and regulatory requirements

Case in point: JB Weld

Recently, JB Weld achieved over 30% efficiency improvement after implementing a QuantumPak Q800CGV-FS with automated gas-flush/vacuum, synchronized nozzles, and the small-bag fingers system. Automation didn’t just speed up their line – it transformed their workflow.

This is the future in motion.

Trend #2: Sustainability Drives Material Innovation & Packaging Redesign

Sustainability has moved beyond a consumer preference – it’s now a regulatory and retailer requirement in many markets. Major retailers, distributors, and global brands are mandating packaging that reduces waste, improves recyclability, and minimizes environmental impact.

Sustainable materials reshaping the industry

Manufacturers are transitioning toward:

- Mono-material films that are more recyclable

- Biodegradable packaging components

- Lightweight materials that reduce shipping impact

- Compostable films for specific product categories

- Reduced-plastic structures for pouches and bags

These material shifts come with new challenges. Many sustainable films behave differently during sealing—they require precise temperature control, consistent pressure, and reliable conveying systems to maintain seal integrity.

Equipment must evolve as materials evolve

Advanced sealers—like QuantumPak’s Q800C, Q800CG, and washdown Q800C-N4X—are built to handle a wide range of emerging films with:

- Tight temperature regulation

- Precision conveyor synchronization

- Reliable pressure control

- Higher uptime and lower variance

- NEMA 4X washdown options for sanitary operations

Sustainability also means reducing waste

Waste reduction is now a KPI. That includes:

- Less product giveaway

- Fewer rejected bags

- More accurate weighing systems

- Inline inspection

- Improved shelf-life with gas-flush technology

Sustainability in 2026 is a combination of material innovation, equipment performance, and process efficiency. QuantumPak offers a wide selection of custom packaging bags designed for strength, freshness, and shelf appeal, all in a one-stop solution minimizing logistics.

Trend #3: Precision, Data, and Smart Technology Take Center Stage

As packaging lines grow more sophisticated, companies are shifting from reactive to data-driven, real-time control.

Smart technology upgrades shaping 2026

CPG manufacturers are embracing:

- PLC-driven controls with HMI touchscreens for easier operation

- Data capture for code dating, lot tracking, and traceability

- OEE (Overall Equipment Effectiveness) monitoring

- Predictive maintenance alerts

- Automated calibration for weighers and fillers

- Smarter sensors for temperature, pressure, and vibration

Precision is no longer optional—especially for companies supplying regulated industries like food, pet food, and nutraceuticals.

Why precision matters

Precision reduces:

- Product giveaway

- Out-of-spec weights

- Seal failures

- Shelf-life issues

- Customer complaints

- Retailer chargebacks

Smart machines help operators identify issues before they impact production.

TIJ printers: a perfect example of smarter packaging tech

Thermal Inkjet (TIJ) printers are rapidly replacing manual code dating and older print technologies. Benefits include:

- Instant, crisp printing

- Reduced operator error

- Faster line speeds

- Effortless integration

- Accurate lot and date coding

- Minimal maintenance

A TIJ system can improve coding efficiency as well as helping QC teams maintain traceability without slowing production.

Looking Ahead: The Packaging Line of 2026

The packaging line of 2026 will be built on three foundations:

- Automatisation – solving workforce gaps and increasing throughput

- Sustainability – balancing performance with environmental responsibility

- Precision + Smart Data – delivering consistent, compliant, digital-ready production

Companies that invest in these pillars today will be the industry leaders of tomorrow.

At QuantumPak, we’re committed to engineering equipment that supports these shifts—from advanced band sealers to vibratory weighers, gas-flush systems, washdown machines, and integrated automation solutions.

If your 2026 goals include efficiency, sustainability, or higher output, we’re ready to help you get there.